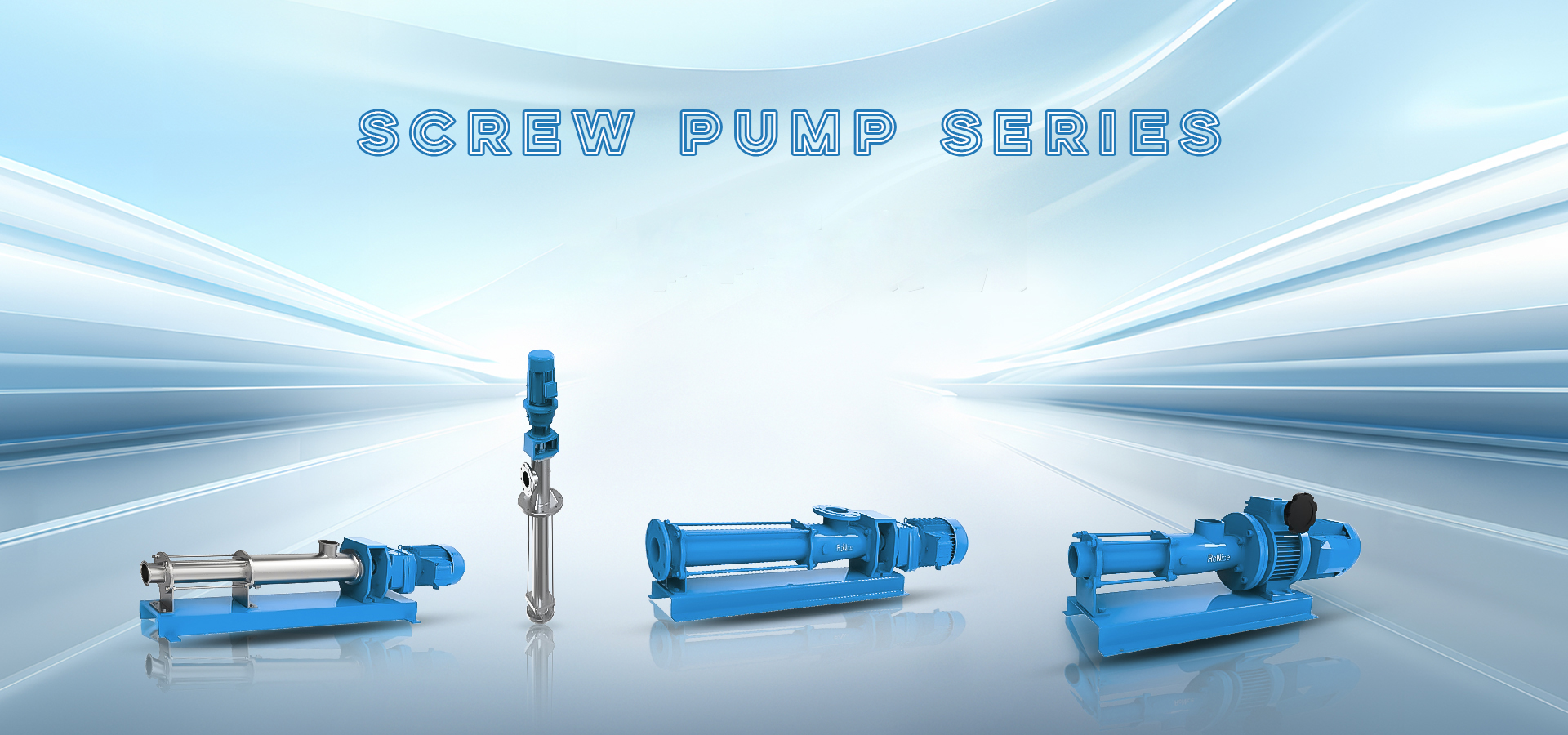

Introduction and application fields of micro screw pumps

Micro screw pumps can be matched with different motors according to customer needs, among which the matching servo motor has extremely high accuracy. The common matching in the dispensing machine and dispensing machine industry is a stepper motor. Generally, customers in the industry can also choose to match low-energy micro gear reduction motors.

The micro screw pump has strong self suction ability, stable pressure and flow rate, and small axial size. It can choose the pump speed according to different conveying materials.

The micro screw pump adopts a sanitary grade clamp type connection, which separates the feed body and the mounting bearing bracket independently, making it easy for users to quickly and thoroughly clean the inner wall without disassembling the motor end, making it easy to switch between other fluid materials. At the same time, we can also customize our own unique pump types according to the actual needs of users.

Application fields of micro screw pumps

1. Electronics (Automation) Industry

Epoxy resin adhesive, resin adhesive, polyurethane adhesive, silicone, etc.

2. Chemical industry

Pigment, lubricating oil, spice, dye, emulsified asphalt, emulsified rubber, catalyst, paint and coating synthetic fiber liquid, viscose liquid, polymer, flocculant, precipitator, lime milk, liquid daily necessities, resin, calcium carbonate, titanium dioxide, styrene butadiene latex, additives, etc.

3. Food industry

Syrup, mashed potatoes, dairy products, chocolate, soy sauce, jam, batter, meat filling, yeast, starch solution, peanut butter, cream drinks, etc.

4. Paper industry

Transporting different concentrations of glue coating machines, brighteners, coagulants, talcum powder, deinking agents, various coatings, black and white liquids, as well as heavy oils in alkali recovery, and transporting pulp chemicals.

5. Military industry

Numerous fields such as university curriculum research.