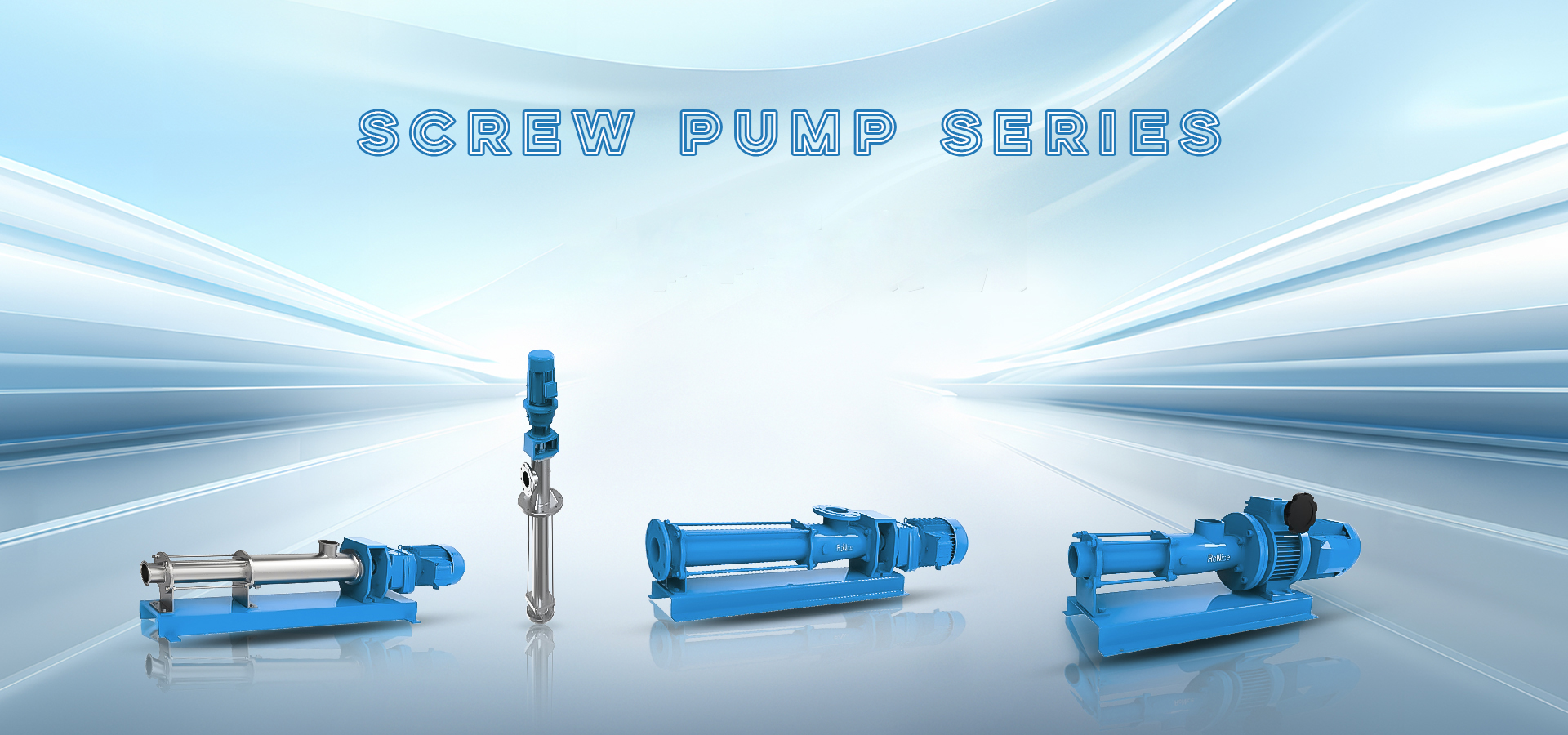

Screw pump flow regulation method

The flow rate of the screw pump can be adjusted in the following ways to meet different process requirements:

1.Adjust the speed: by adjusting the speed of the motor, you can directly affect the flow of the screw pump. Generally, the higher the speed, the greater the flow of the pump. This method is simple and direct, but attention should be paid to the load capacity and heat dissipation of the motor.

2. Adjust the import and export valve: by changing the opening of the import and export valve, you can control the resistance of the fluid through the screw pump, and then adjust the flow rate. The greater the valve opening, the smaller the resistance and the greater the flow rate. However, please note that over-opening the valve may cause the efficiency of the pump to decrease.

3.Change the internal structure: in some cases, by replacing the internal structure of the screw pump (such as the number of screws, shape, length, etc.), you can change the flow characteristics of the pump.

4. The use of frequency converter: the installation of frequency converter can achieve accurate control of the motor speed, so as to adjust the flow of the screw pump more flexibly. The frequency converter can automatically adjust the speed according to the actual needs, achieve accurate flow control, and has energy saving effect.

It should be noted that different flow regulation methods may have different effects on the performance and service life of the screw pump. When selecting the adjustment mode, the working conditions, load conditions, service life and economic benefits of the pump should be considered comprehensively, and the most suitable method should be selected. At the same time, when regulating the flow, follow the relevant operating rules and safety requirements to ensure the safety and effectiveness of the operation.

Key words: screw pump, screw pump flow regulation

- Previous:Screw pump daily maintenance

- Next:The company won the title of