What are the reasons for the overheating of screw pumps?

As a commonly used fluid conveying equipment, screw pumps are widely used in various fields. However, during use, sometimes the screw pump may overheat, which not only affects the normal operation of the pump, but may also cause safety issues. This article will propose some reference directions for the causes of overheating in screw pumps.

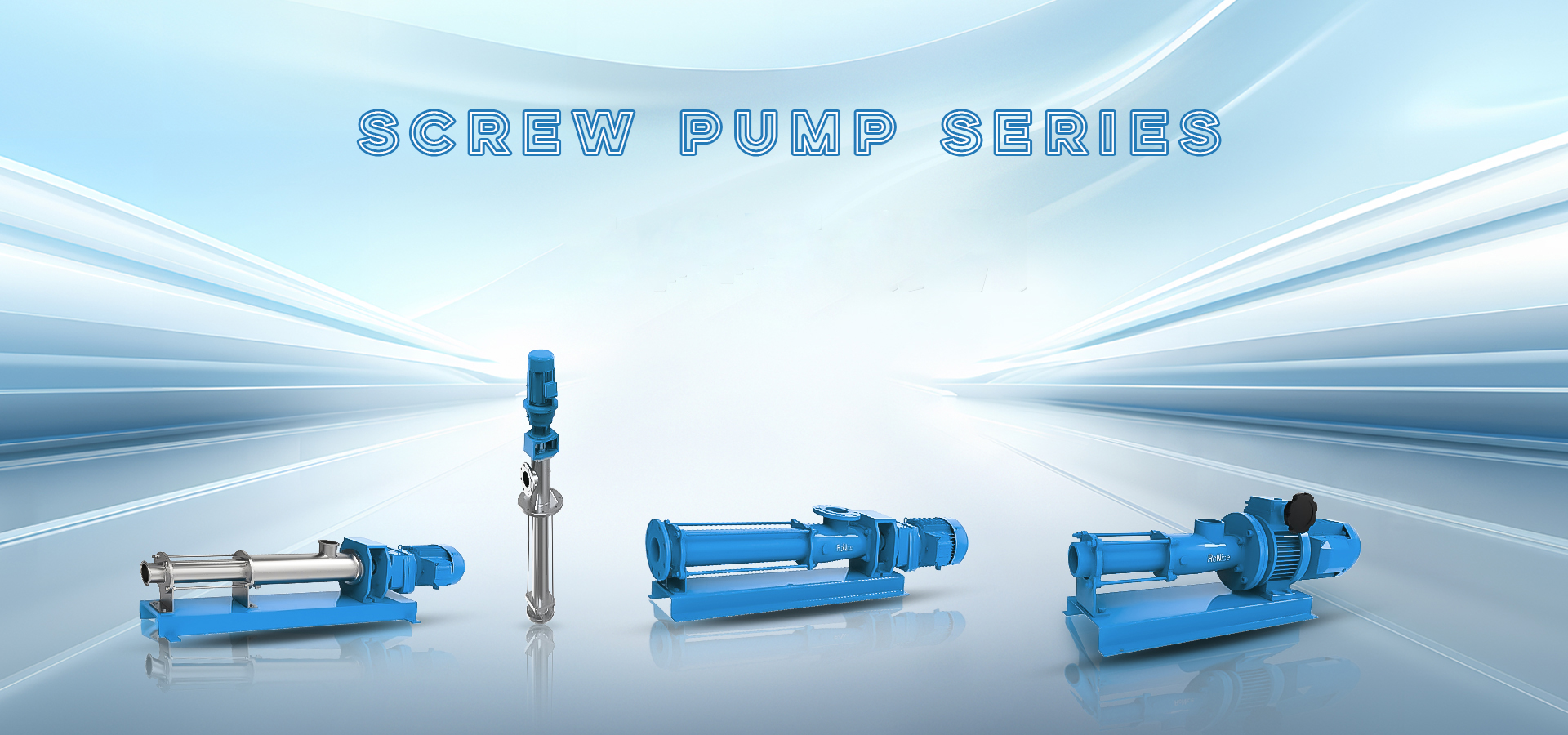

1. We need to understand the working principle of screw pumps

A screw pump is a type of pump that transports liquid through the rotational motion of a screw. It mainly consists of screws, pump bodies, bearings, and seals. When the screw rotates inside the pump, the liquid is sucked in and squeezed out as the screw rotates. During this process, the screw pump will generate a large amount of heat.

What are the reasons for the overheating of screw pumps?

1) Mechanical friction. The friction between the internal components of a screw pump is one of the main reasons for generating heat. Long term operation can cause wear on components such as bearings and seals, thereby increasing friction and generating a large amount of heat. In addition, foreign objects entering the pump can also cause mechanical friction, leading to an increase in temperature.

2) Fluid friction. When conveying high viscosity fluids, the friction between the fluid and the pump inner wall generates a large amount of heat, leading to an increase in pump body temperature. The higher the viscosity of a fluid, the more heat is generated by friction.

3) Lack of lubrication and cooling. A screw pump requires a good lubrication and cooling system to maintain normal operation. If the lubricating oil supply is insufficient or the cooling water circulation malfunctions, the heat cannot be dissipated in a timely manner, causing the pump body to overheat.

4) Motor malfunction. If the driving motor of the screw pump malfunctions, such as a short circuit in the winding or damage to the bearings, it can cause the motor to overheat, resulting in the entire pump system overheating.

5) Media issues. If the conveying medium contains impurities or corrosive substances, it will cause damage to the internal components of the pump and cause local high temperatures. In addition, the high temperature of the medium can also cause an increase in the temperature of the pump body.

3. How can we solve the problem of screw pump overheating?

1) Regular maintenance and inspection. Regularly maintain and inspect the screw pump to ensure that all components are intact and that the lubrication and cooling systems operate normally. Replace severely worn components in a timely manner to avoid excessive heat generated by mechanical friction.

2) Choose appropriate lubricating oil and cooling water. Select appropriate lubricating oil and cooling water according to the working conditions of the screw pump to ensure that the pump receives sufficient lubrication and cooling during operation. At the same time, regularly check the supply of lubricating oil and cooling water to ensure they are sufficient and leak free.