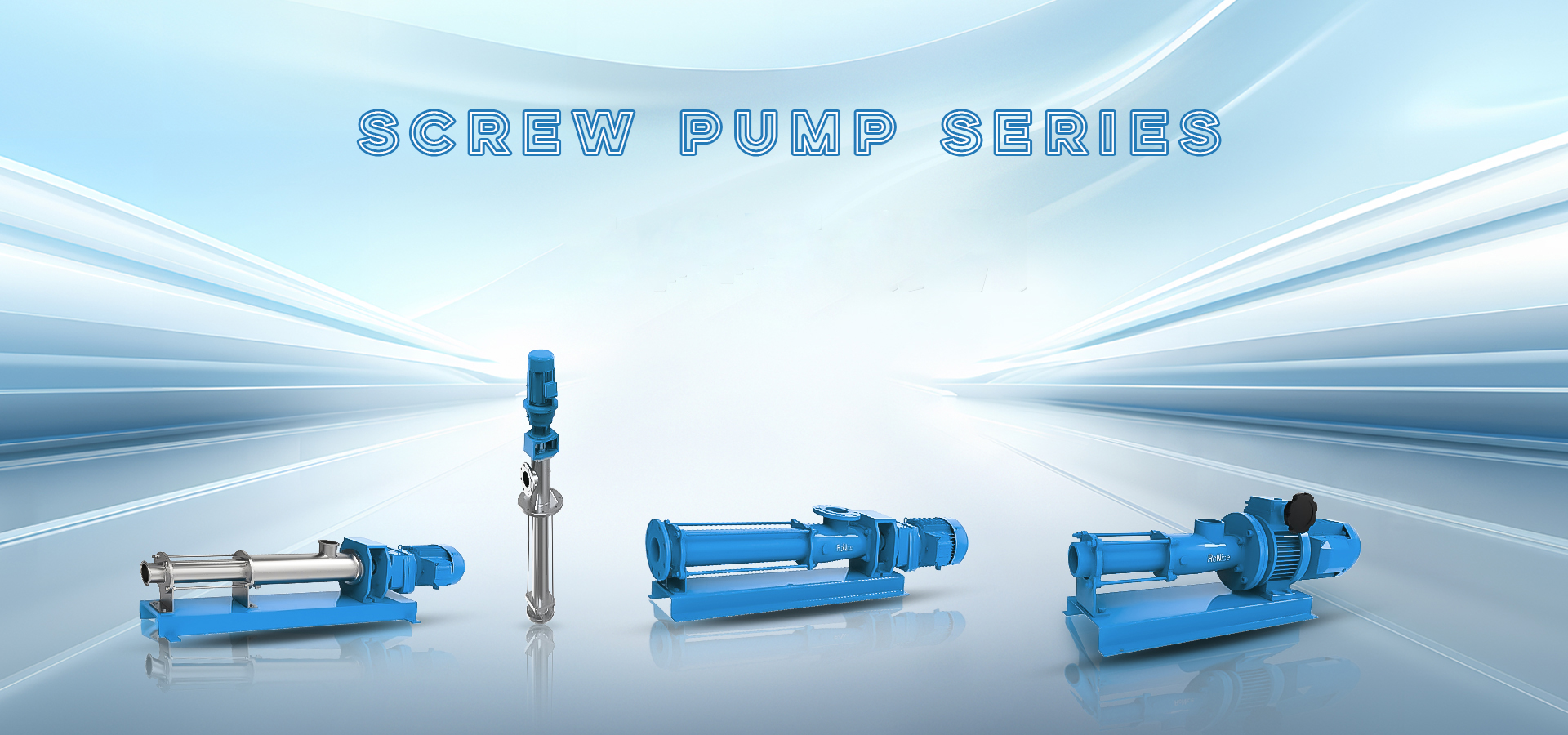

Detailed knowledge of screw pump

Screw pump, as an efficient positive displacement pump, its core working principle lies in the precise coordination of rotating motion between the screw and the bushing, so as to achieve continuous liquid transport. The simplicity of its design, the stability of the flow output, the tiny pressure pulsation, the ease of adjustment, and the low noise characteristics make the screw pump occupy a place in many industrial fields such as oil extraction, chemical processing, pharmaceutical production, paper manufacturing, food processing and environmental protection.

Classification and working principle

Classification: According to the number of screws, screw pumps can be divided into single screw pumps, double screw pumps and three screw pumps. Each type is suitable for different media characteristics, pressure ranges and displacement requirements.

Working principle of single screw pump: the motor drives the pump shaft to rotate, and the screw rotates around its own axis and along the inner wall of the bushing to form a continuous sealing chamber. With the rotation of the screw, the liquid in the sealing chamber is gradually pushed forward and finally discharged from the pump body.

Double screw pump and three screw pump: the working principle of these two types of pumps is similar, and they form a sealed chamber through the mesh of a number of screws to achieve liquid transportation. The symmetry of the structure allows the radial force on the active screw to be balanced, thus improving the reliability and service life of the pump.

Characteristics and advantage

1.High reliability: Compact structure, fewer moving parts, reducing the possibility of failure.

2.Long life: The physical contact between the screw and the bushing wears slowly, extending the service life of the pump.

3.Flow stability: The output flow is proportional to the speed, easy to adjust and stable and reliable.

4.Strong adaptability: can handle all kinds of viscosity, temperature and liquid containing impurities and particles.

5.Low noise: Smooth operation, low vibration, low noise level.

6.Easy maintenance: The main parts are easy to disassemble and replace, reducing maintenance costs.

Precautions for use

Installation requirements: Ensure that the pump body is installed horizontally to avoid uneven wear caused by gravity.

Pipeline cleaning: regularly check and clean the pipeline and inlet and outlet valves to prevent clogging affecting the normal operation of the pump.

Shutdown maintenance: After shutdown, the liquid in the pump body and pipeline should be emptied to prevent the residual liquid from corrosion or solidification of the equipment.

Safe transportation: When transporting flammable and explosive media, nitrogen or other inert gases should be used to seal it to ensure the safety of the transportation process.

To sum up, screw pumps play an important role in many industrial fields with their unique advantages. Correct selection, installation and maintenance of screw pump is of great significance for ensuring production safety and improving production efficiency.