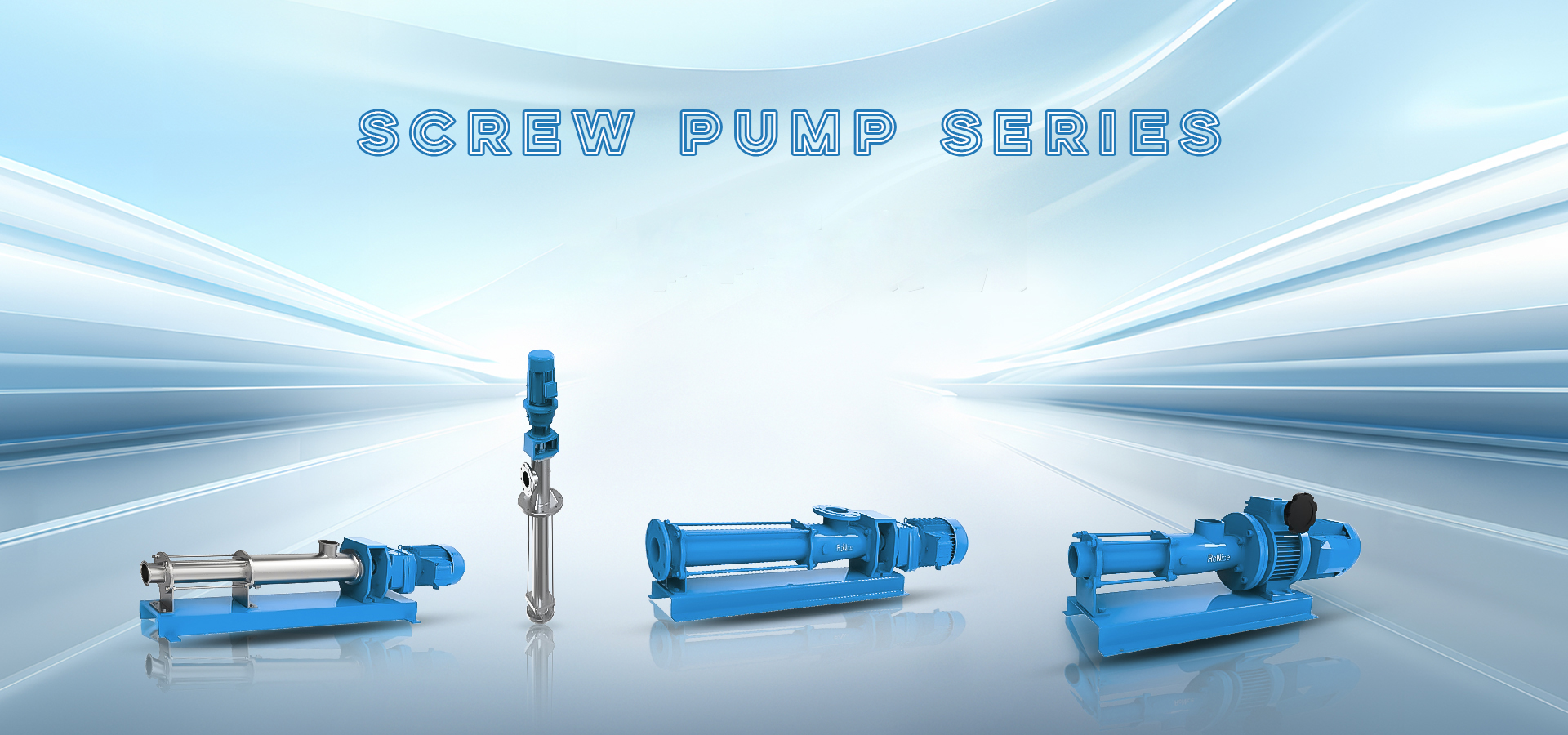

Screw Pump Working Principle

In a screw pump, due to the very small clearance between the screw and the liner, and the high meshing line speed of the helical grooves (generally 20–40 m/s), the liquid is continuously drawn in, compressed, and discharged during the meshing process.

1.Suction Process:

As the screw rotates, the suction created by the rotation of the threads and the convective action of the liquid causes the liquid to enter the screw pump from the inlet.

2.Compression Process:

As the screw turns, the liquid is progressively squeezed out by the pressure applied to the threads. Due to the compressibility of the gas, the volume of the gas decreases. This cyclical process forms a continuous volumetric change — the process of compressing the gas from the suction chamber and discharging it to the atmosphere is called the compression process; conversely, the process of discharging or releasing gas is referred to as the discharge process.

3.Discharge Process:

As the screw continues to rotate (at a higher speed), it eventually reaches its limit position and stops (at a lower speed).