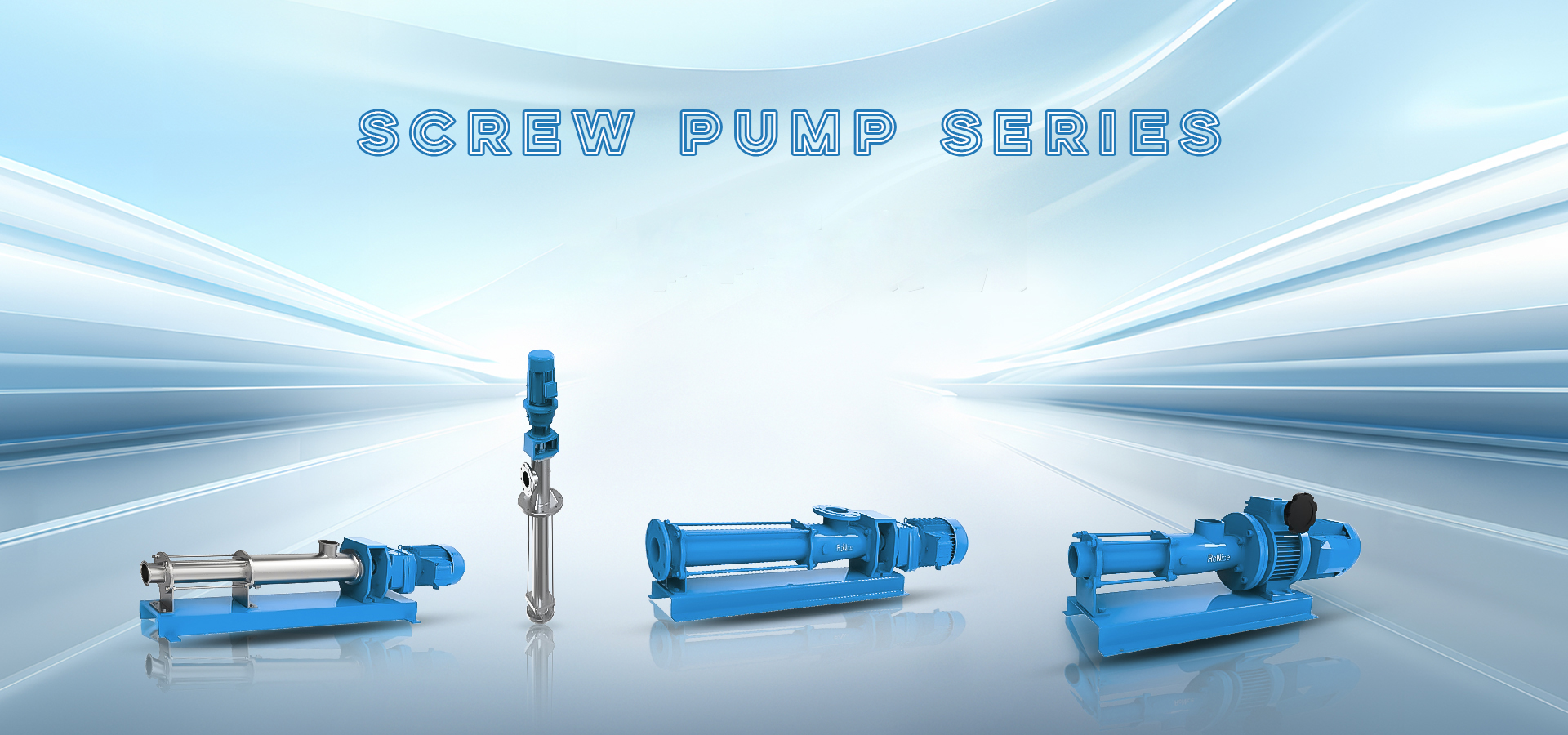

Characteristics and Applications of Screw Pumps

Characteristics:

Simple Design: Easy to manufacture and maintain.

High Flow Rate: Low head loss and high operational efficiency.

Versatile Compatibility: Suitable for liquids with varying viscosities and solid particles.

Excellent Sealing: Strong corrosion resistance.

Low-Speed Operation: Reduces mechanical wear and avoids cavitation.

Wide Flow Channels: Suitable for transporting liquids containing solid substances.

Semi-Open Pump Casing: Allows for easy observation of internal operating conditions.

Applications:

Screw pumps have a wide range of applications across various fluid transport sectors:

Petrochemical Industry: Transport of petroleum products and chemical raw materials.

Environmental Water Treatment: Handling urban sewage, industrial wastewater, and water treatment processes.

Food and Pharmaceutical Industries: Transport of food ingredients and pharmaceutical products (e.g., milk, juice, medicinal liquids).

Marine Transport: Circulation of marine fuel, lubricants, and bilge water.

Construction: Transport of construction materials such as concrete and mortar.

Parameter Introduction:

Key parameters of screw pumps include:

Flow Rate (Q): Measured in m³/h or L/min, indicating the volume of liquid pumped per unit time.

Head (H): Measured in meters, representing the vertical lifting height of the liquid.

Speed (n): Measured in r/min, reflecting the rotation speed of the screw pump.

Power (P): Measured in kW, indicating the power required to pump the liquid.

Temperature (T): Measured in °C, specifying the suitable temperature range for the pumped liquid.

Selection and Usage Notes:

Precise Selection: Choose based on actual needs, considering flow rate, head, speed, and power.

Material Compatibility: Consider the characteristics of the pumped liquid and select appropriate pump casing and screw materials.

Regular Maintenance: Implement periodic inspections and maintenance to ensure stable operation and extend the pump's lifespan.