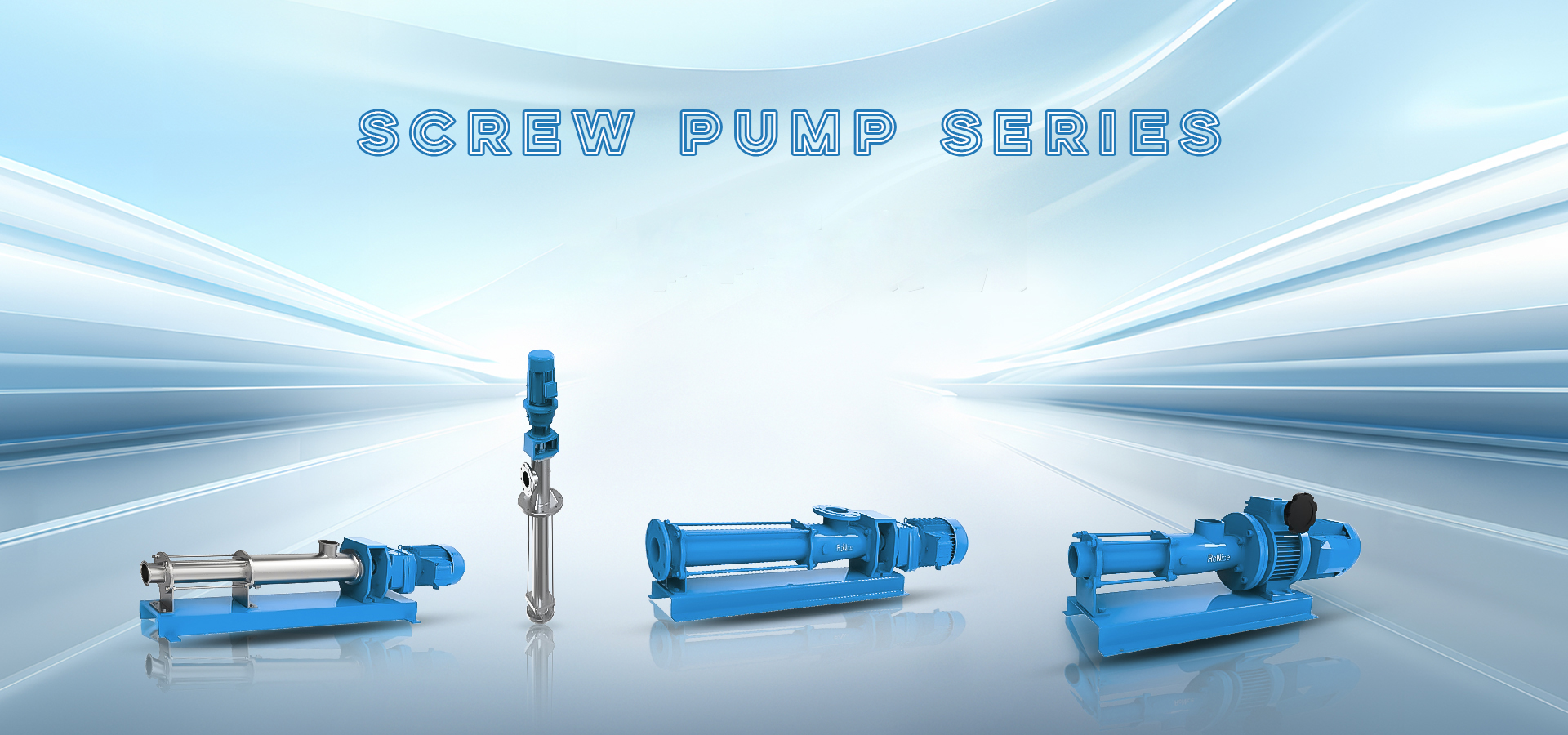

Working principle of screw pump

The working principle of the screw pump is mainly based on the interaction between the screw and the screw inside the pump housing, and the liquid or gas is transported from the low pressure area to the high pressure area by rotating the screw. The specific process is as follows:

Screw rotation and axial movement : The core of the screw pump is one or more rotating screws, which are installed in the pump housing, one end is the suction end, the other end is the discharge end. When the screw rotates, its spiral surface engages with the thread formed on the inner surface of the pump housing, pushing the screw to move slowly in the axial direction. preprocess.

Suction process : With the rotation of the screw, the spiral surface is gradually pushed forward, thus forming a gradually increasing space between the screw and the pump housing, that is, the pump chamber. This increased space creates a low pressure area at the suction end, allowing external liquids or gases to be drawn into the pump chamber.

Closed cavity formation and movement : The spiral surface of the screw is closely matched with the screw threads in the pump housing to form one or more closed cavities. These cavities move forward in an axial direction with the rotation of the screw, enclosing the inhaled liquid or gas and pushing it forward.

Discharge process : When the closed chamber moves to the discharge end, the liquid or gas is compressed and discharged out of the pump because the pressure at the discharge end is higher than that at the suction end. This process is repeated through continuous rotation of the screw, thus achieving continuous delivery of liquid or gas.

The working principle of screw pump is simple and efficient, and it has the advantages of large flow rate, stable pressure, low noise, and being able to transport high-viscosity media, etc., which has been widely used in petroleum, chemical, food, pharmaceutical, construction and other industries.