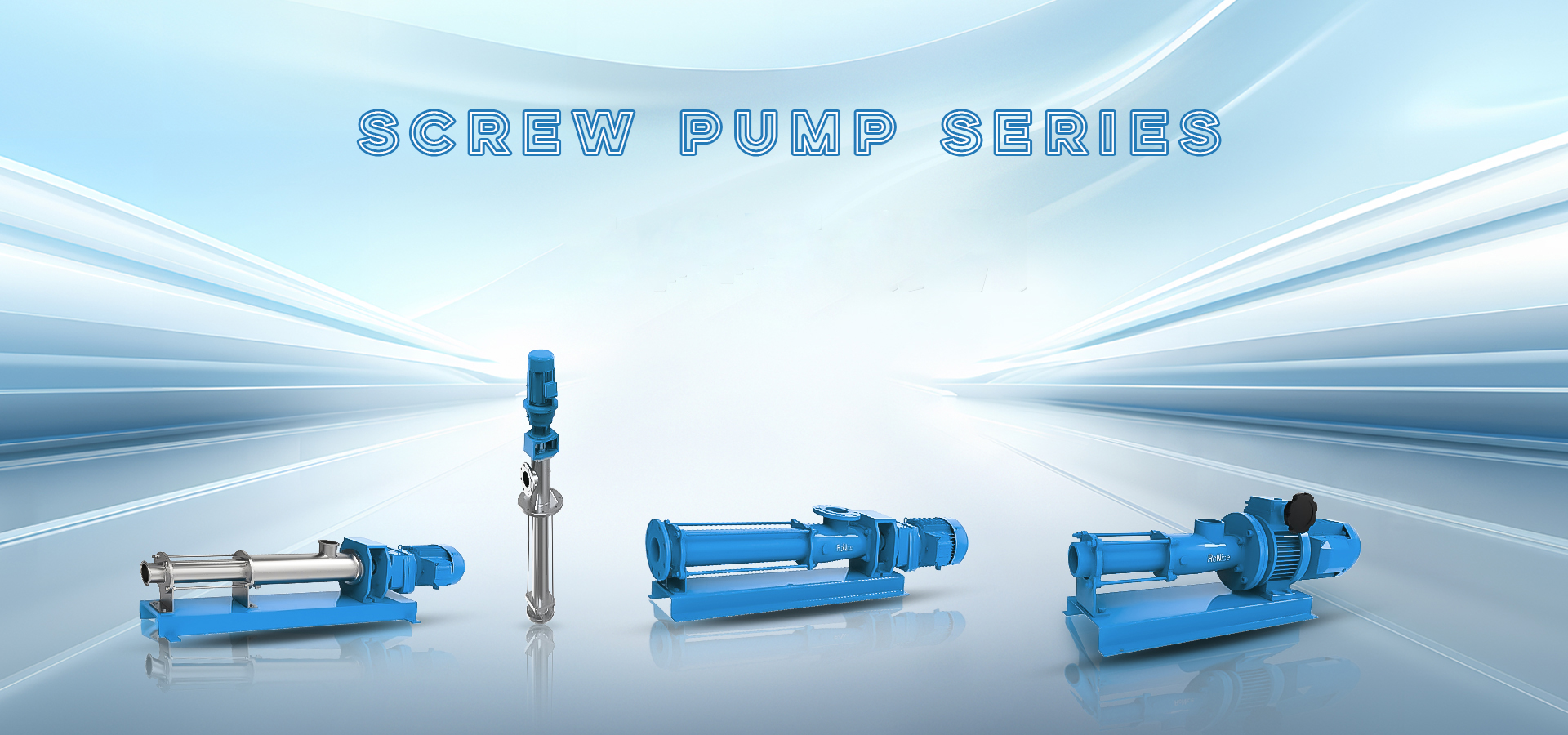

Advantages and disadvantages of screw pump

The performance of the screw pump is comprehensively reflected by the parameters of flow, power, speed, caliber, temperature, etc. These parameters not only reveal its powerful functional characteristics, but also include the advantages and disadvantages of the screw pump. Below, we will elaborate on the advantages and disadvantages of the screw pump.

Advantages:

Wide pressure and flow range : screw pump can provide 3.4 to 340 kgf/cm² pressure, flow up to 100cm³/min, to meet a variety of needs.

Extensive liquid adaptability : Can handle a wide range of liquid types and viscosities.

High speed capability : Thanks to the low inertia force of its internal rotating parts, the screw pump allows for extremely high speed operation.

Excellent suction and self-priming : ensures efficient and stable fluid intake.

uniform flow and low vibration : Smooth operation, reducing potential damage to equipment.

High tolerance for gas and dirt : Less sensitive to gas and dirt entering the pump body than other rotary pumps.

strong structure and convenient maintenance : strong design makes the installation and maintenance process simple and fast.

Shortcoming:

High machining and assembly accuracy : the processing and assembly of screw need to meet high standards, which increases the manufacturing cost.

sensitive to changes in liquid viscosity : changes in liquid viscosity will directly affect the performance of the pump.

may produce vibration and noise : in some cases, the pump body may vibrate violently or produce noise, affecting the working environment.

In summary, screw pump with its high pressure, large flow, high efficiency and other significant advantages, plays an important role in production. Despite some disadvantages, its advantages are still widely recognized and have been applied in many fields.