What are the main types of dispensing valves?

In modern industrial production, dispensing technology, with its high precision and flexibility, has become an indispensable part of many manufacturing processes. As the core component of the dispensing system, the dispensing valve has various types, each with unique characteristics and application scenarios. Below, we will delve into several mainstream dispensing valve types and their applications in the industrial field.

First, the main types of dispensing valves.

Needle dispensing valve

Features : The precise needle-like structure is used to adjust the flow rate and dispensing speed of the glue by precisely controlling the glue pressure.

application : because of its high precision and flexibility, it is widely used in the fine assembly of electronic products (such as mobile phone touch screen, semiconductor packaging), medical device manufacturing and other fields requiring high precision dispensing.

valve type dispensing valve

features : Using a similar valve switching mechanism, can accurately control the opening and closing of the glue, suitable for high viscosity glue accurate dispensing.

application : common in liquid crystal display manufacturing, precision machining, auto parts assembly, especially in the dispensing scene requiring high accuracy and stability.

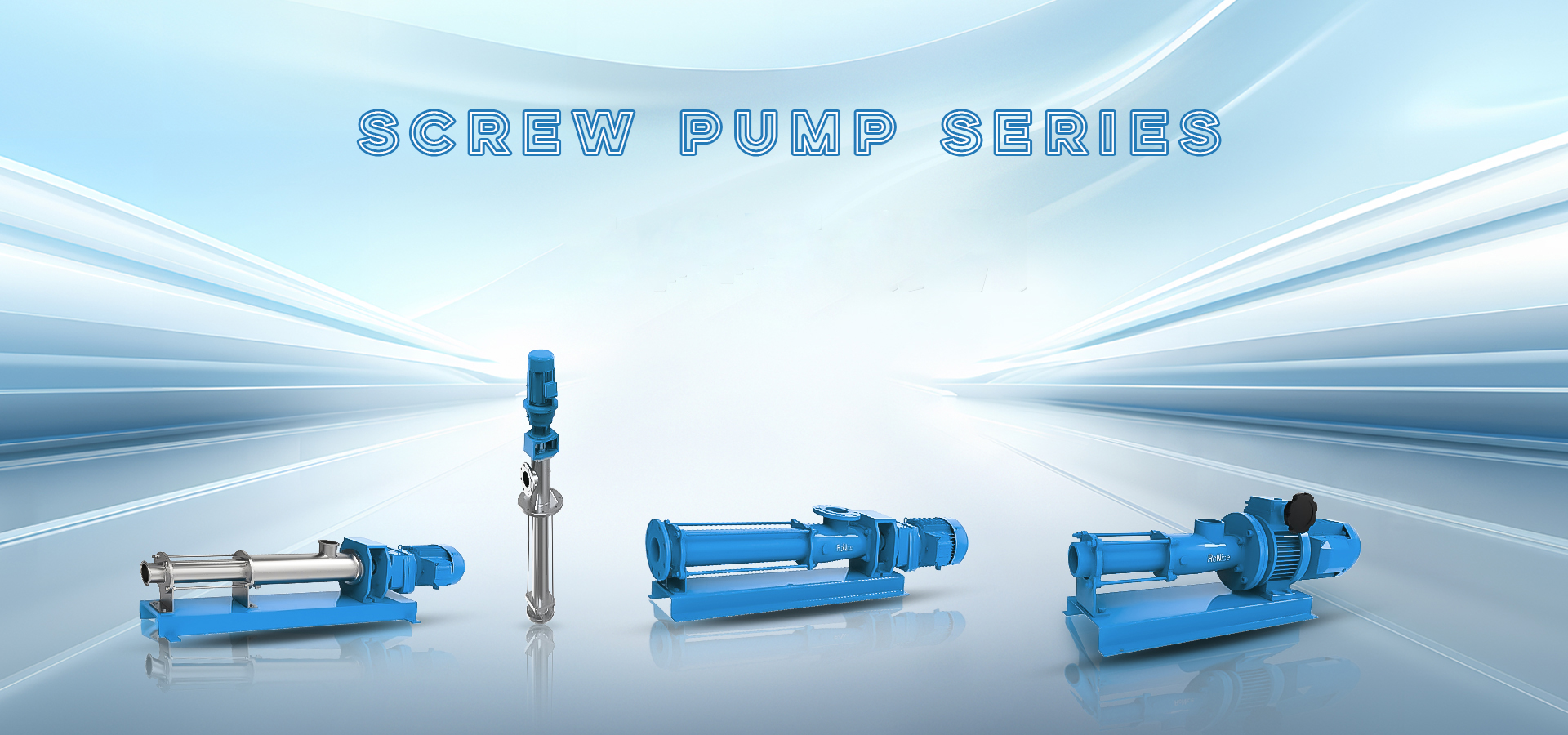

screw dispensing valve

Features : The high viscosity glue is evenly extruded from the container by the rotating movement of the screw, which is suitable for dealing with large flow and high viscosity glue.

application : excellent performance in the sizing process of sealant, silica gel, epoxy resin and other materials, widely used in building sealing, automobile manufacturing, industrial equipment sealing and other fields.

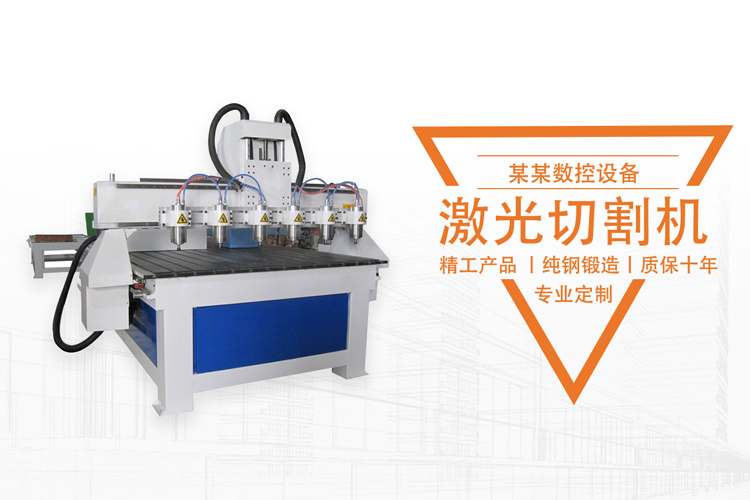

extrusion dispensing valve

Features : The operation is similar to the glue gun, can continuously and evenly extrude glue, suitable for large area coating and sealing.

application : commonly used in furniture manufacturing, architectural decoration, automotive interior parts glue, especially in the need to quickly and efficiently cover a large area.

preprocess