Screw pump selection and application

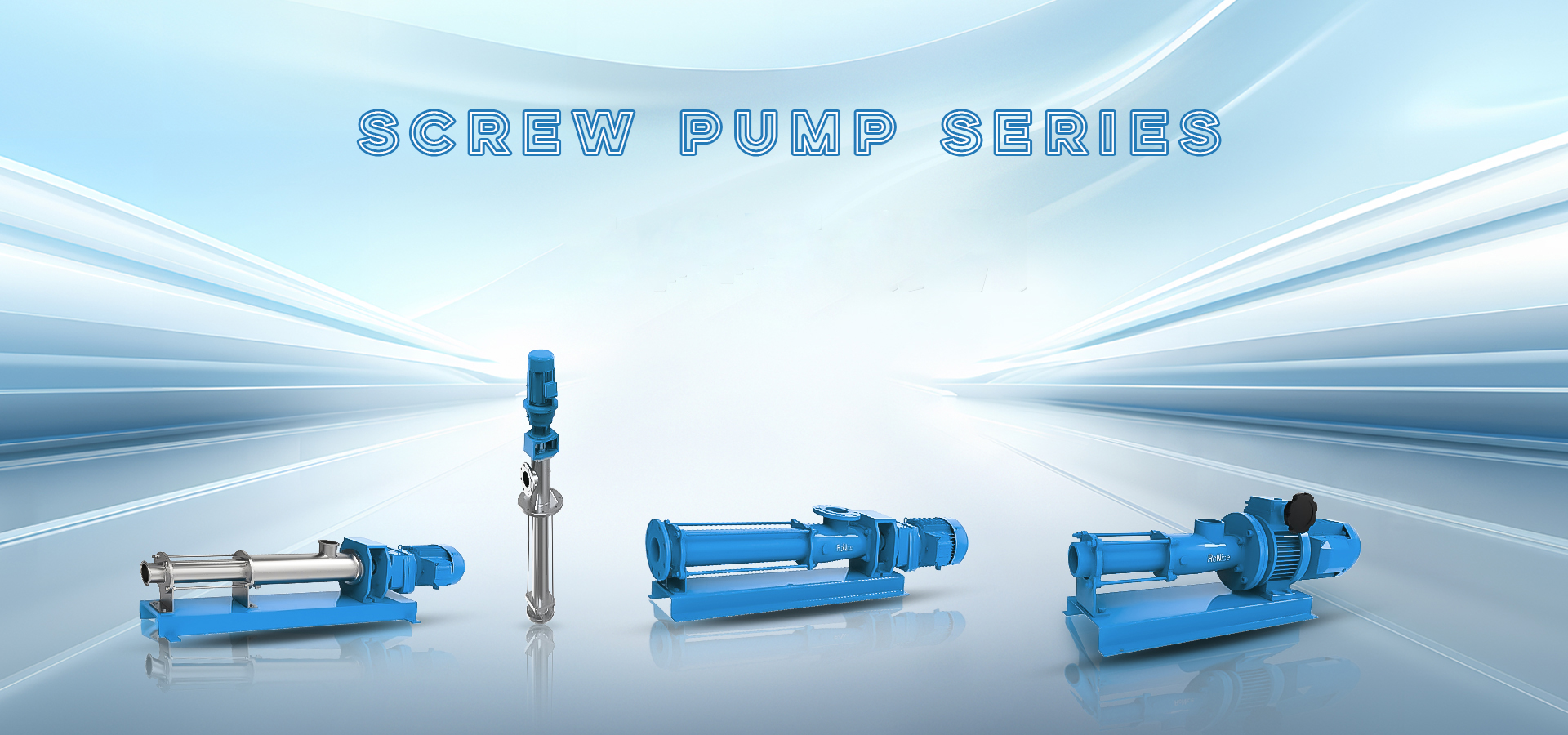

Screw pump with its variable transport, strong self-priming capacity, reversibility and the ability to handle liquid containing solid particles, widely used in sewage treatment plants in water, wet sludge and flocculant liquid transportation. When choosing a screw pump, it is necessary to follow the principles of economy, rationality and reliability to ensure smooth production and reduce maintenance costs. The following are some suggestions for screw pump selection and daily maintenance:

First, reasonable control of screw pump speed

The flow rate of the screw pump is directly related to the speed. Although the high speed can increase the flow rate and head, it will significantly increase the power consumption, aggravate the wear between the rotor and the stator, and shorten the service life of the pump. Therefore, it is recommended to control the speed of the screw pump below 300 revolutions per minute through the deceleration mechanism or the speed regulation system to balance the flow demand with the long life of the pump.

Second, optimize the quality of screw pump

In the choice of screw pumps, imported products are often well-designed and excellent materials, but the price is high and the service response may be insufficient. Although many domestic products are imitated, the quality is uneven. When purchasing, we should consider the cost performance comprehensively, and give priority to low speed, long lead, excellent material of transmission components, and long rated life products to ensure the stable and durable performance of the pump.

Third, prevent debris from entering the pump body

The solid debris in wet sludge is easy to damage the rubber stator of the screw pump. In order to prevent such situations, it is recommended to install a crusher, grille or filter in front of the pump to effectively intercept debris. At the same time, the grille is cleaned regularly to prevent blockage and ensure the smooth operation of the pump pre-treatment system.

Fourth, avoid idling

The screw pump is strictly forbidden to run in the state of cut off material, because dry friction will cause the rubber stator to burn at high temperature instantaneously. Therefore, it is essential to keep the mill running well and the grille unimpeded. Some screw pumps are also equipped with a cut-off stop device, which automatically stops using the vacuum signal generated by the self-priming characteristic to further protect the pump body from damage.

Fifth. Maintain constant outlet pressure