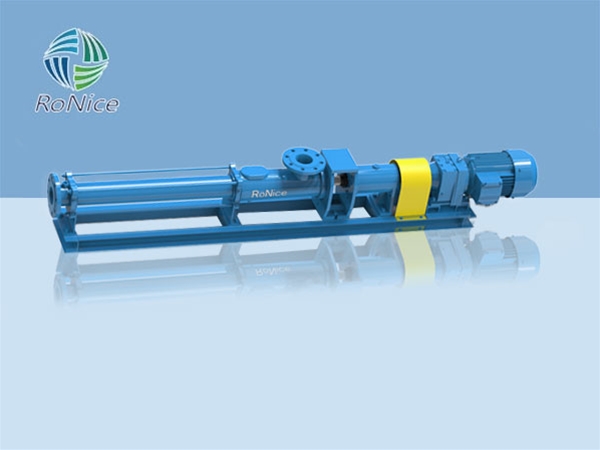

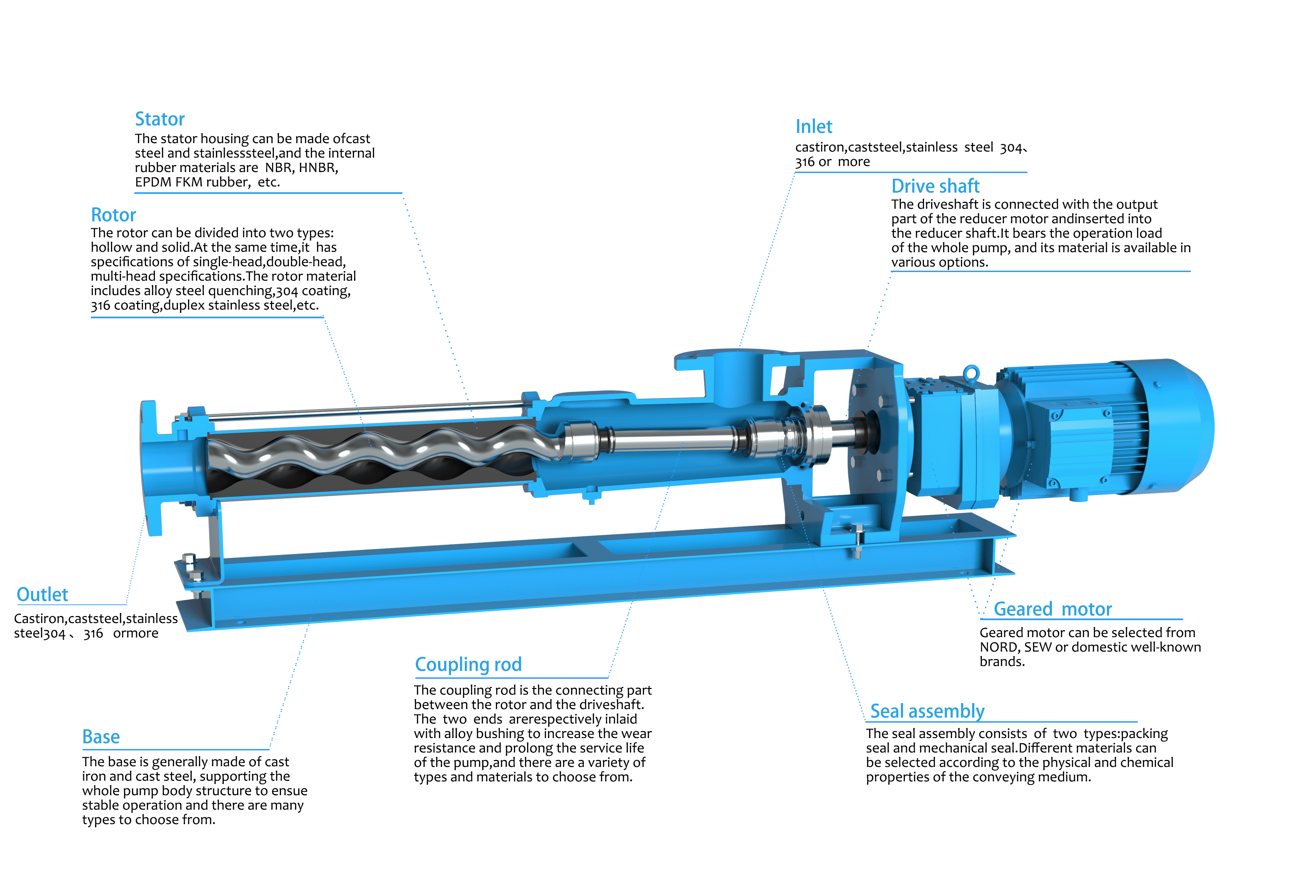

Single Screw Pump With Bearing Bracket Type

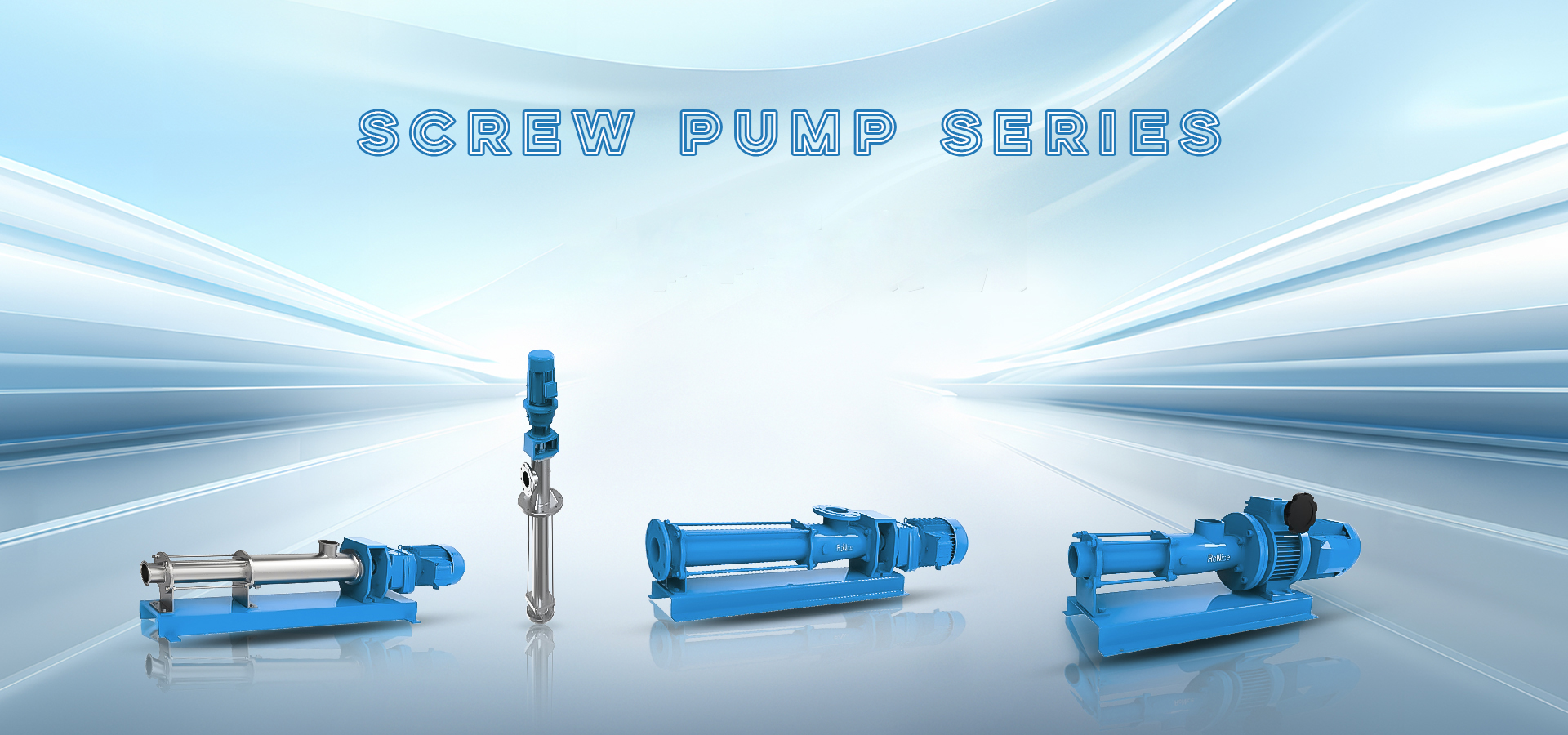

- Type:Screw pump series

- Code:

-

bearing bracket type, pump body extension, in the axial two ends of the installation of stable bearings, higher rigidity, reducer motor through the coupling and the bearing seat connected drive, stronger load bearing capacity. After the axial load bearing capacity is increased, it can match the use of multi-grade or large flow pump, while reducing the axial force of the gear motor, extending the service life and making the equipment run more smoothly. Diesel engine, hydraulic motor, air motor can be widely used to drive the pump body, instead of the reducer motor.

- Product Description

Advantages of screw pump:

1. It can transport high viscosity medium.Depending on the size of the pump,the viscosity of the medium is in the range of 0 centipoise(CPS) to 300,000 centipoise(CPS).

2. It can transport solid particles,grinding particles and fibers.The content can be up to 40% of the medium ingeneral. When the solid in the medium is powdery fine particles,the maximum content can be as high as 70%.According to the size of the pump,the maximum particle size of the solid contained in the medium is 2mm-40mm.

3. The output liquid is continuous and even with stable pressureand small agitation.Therefore ,the composition of the sensitive liquid will not change.

4. Flow rate is directly proportional to speed.The flow can be adjusted by changing the speed.Coupled witha variable speed motor,the pump canbecome a variable pump,whichis very flexible.It can also achieve constant flow control through PLC control.

5. The pressure can be automatically adjusted with the resistance of the output pipeline. Between 0-48(kg/cm2) pressure,the user can easily adjust to the required pressure.In this way, it can not only save energy,but also avoid the influence to the process fow because of too high or too low pressure. Meanwhile it works better through PLC control to achieve constant pressure transmission.

6. Simple structure,less wear,and easy maintenance.

Compared with other types of pumps:

1. Compared with the centrifugal pump,the single screw pump does not need to install alves.It own can forma closed cavity to prevent backflow buffer,and the flow is stable and linear,without large fluctuations.

2. Compared with the plunger pump,the single screw pump has a better self-priming capacity.According to the size of the pump,it can suck up to a height of about 8 meters of water column.

3. Compared with the diaphragm pump,the single screw pump can transport a variety of mixed impurities,and realize the mixed transport of gas,liquid and solid,and can also transport the medium containing solid particles or fibers and a variety of chemical corrosive substances.

4. Different from plunger pump,rotor pump,diaphragm pump and gear pump,single screw pump can be used for pharmaceutical filling and metering,and its metering accuracy is far higher than other pumps.

RSZC bearing bracket type:

- The pump body has been extended, and stable bearings have been installed at both ends of the axial direction for higher rigidity. The deceleration motor is connected to the bearing seat through a coupling for stronger load bearing capacity.

- After the axial load bearing capacity increases, it can be matched with multi-level or high flow pump types for use, while reducing the axial force of the deceleration motor, extending its service life, and ensuring smoother equipment operation.

- Diesel engines, hydraulic motors, and pneumatic motors can be widely used to drive pump bodies, replacing deceleration motors.

- Flow range: 0.1-300m ³/ H.

- Pressure range: 0-2.4Mpa or higher.

Get to know Ronice:

screw pump/screw valve/micro dispensing screw pump